INLINE KEEN EYE

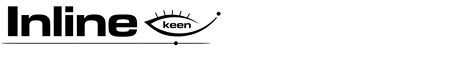

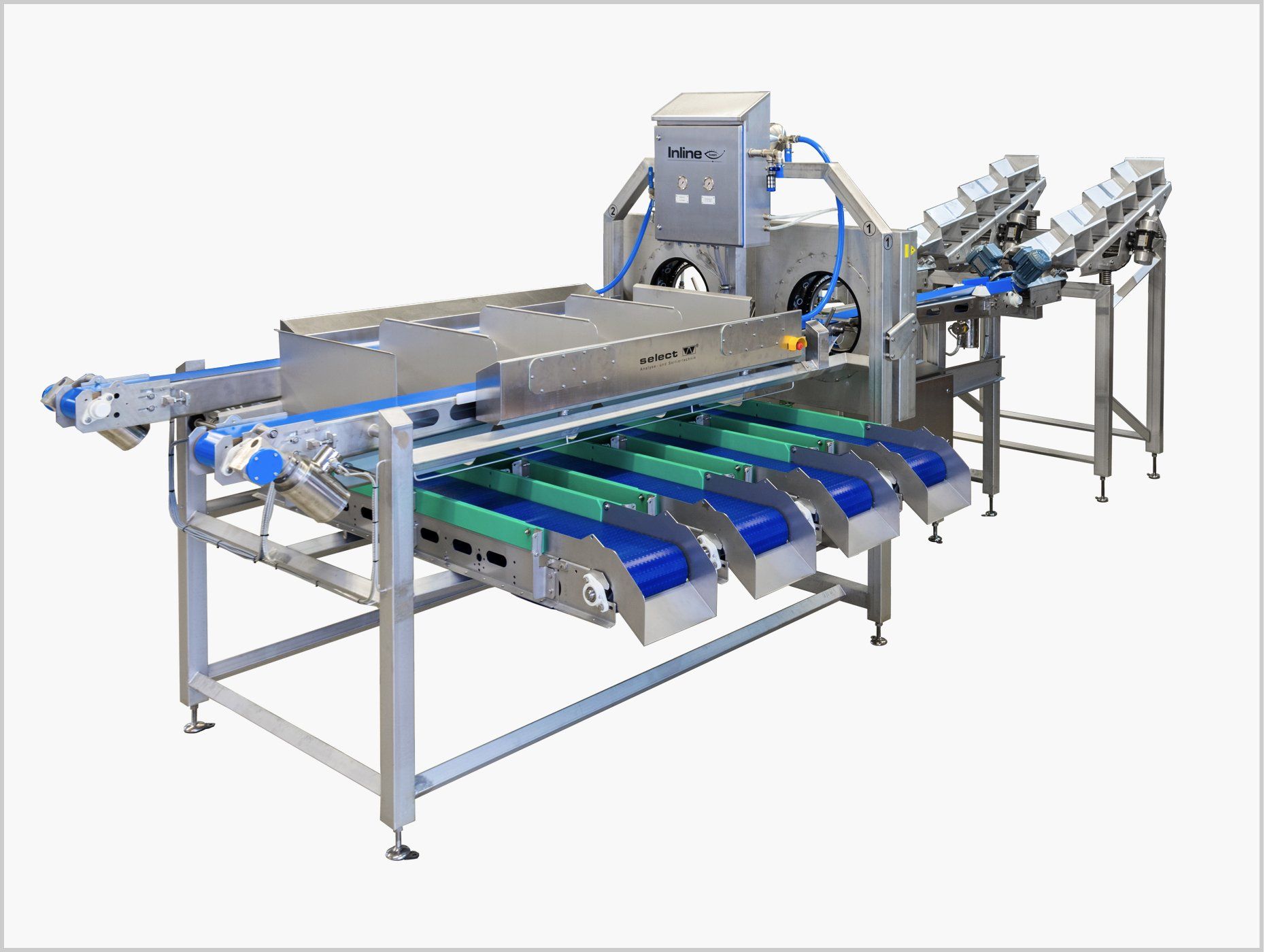

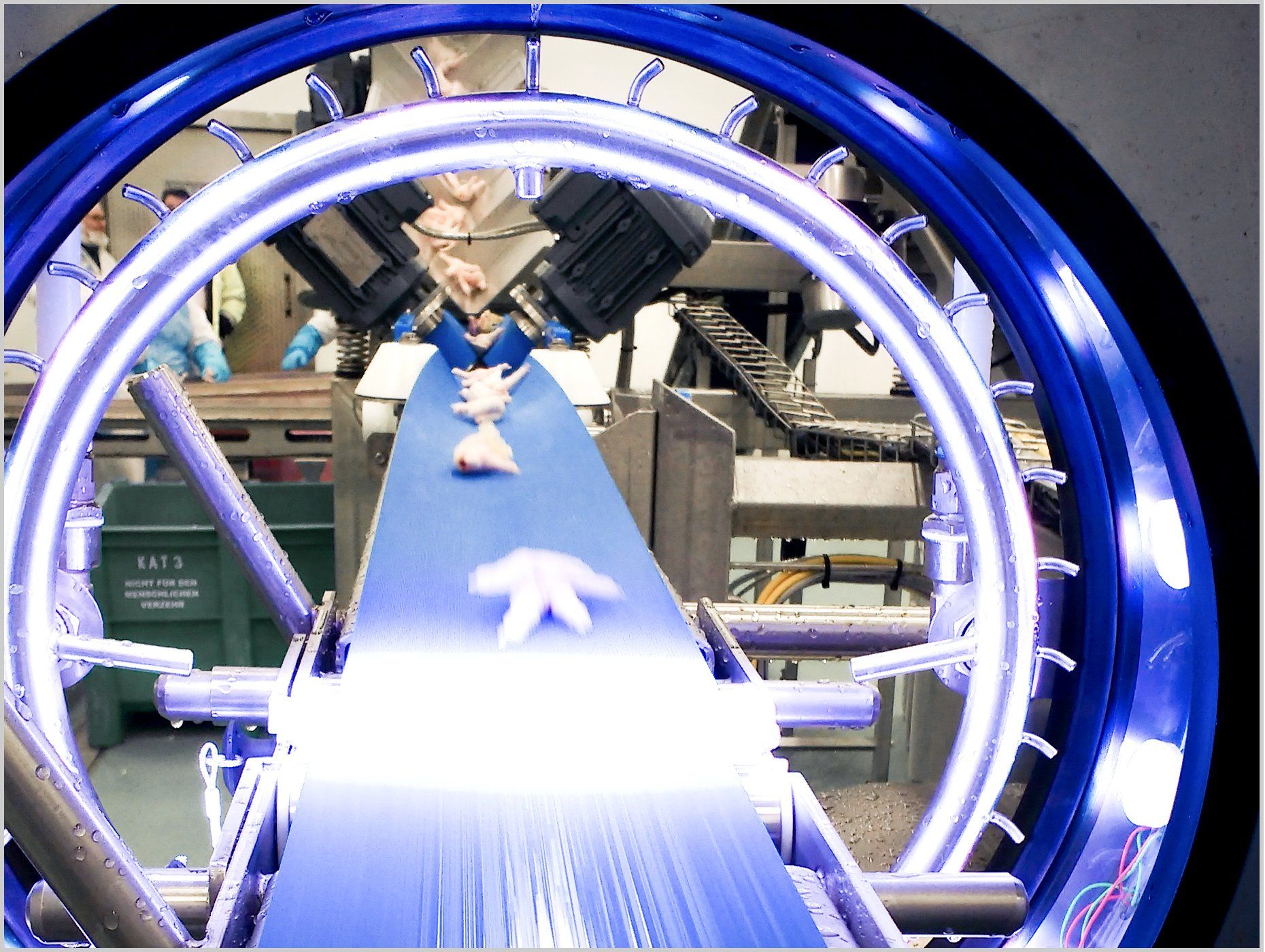

The InLine keen eye takes the renowned accuracy of the Agroselector principle and reapplies it to successfully sort a wider variety of products into a greater number of channels or results.

It has already helped many processing companies, large and small, save cost by reducing labour and improving product yield, quality and consistency.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

info@shareteq.com

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

- Cost saving

Reduction in labour is the main objective of an optical sorter and the InLine keen eye removes 90% of inspection staff. Yield can also be increased by consistent fault detection or new markets can be opened up for individually size/weight graded products.

- Quality improvement

Defective material is removed cleanly and consistently, leaving the finished product to your customer’s specification without the subjective vaguaries of the human eye.

- Variety of sorting possibilities

InLine keen eye identifies defects by colour, measures size in all three dimensions, calculates weight and assesses product shape.

Up to nine sorting results can be provided, which can be separate quality grades or a combinations of quality, size and shape.

- High capacity

InLine keen eye’s capacity can be up to 50 tonnes/hr, depending on the number of parallel sorting lanes and the product size or weight.

- Simple to operate

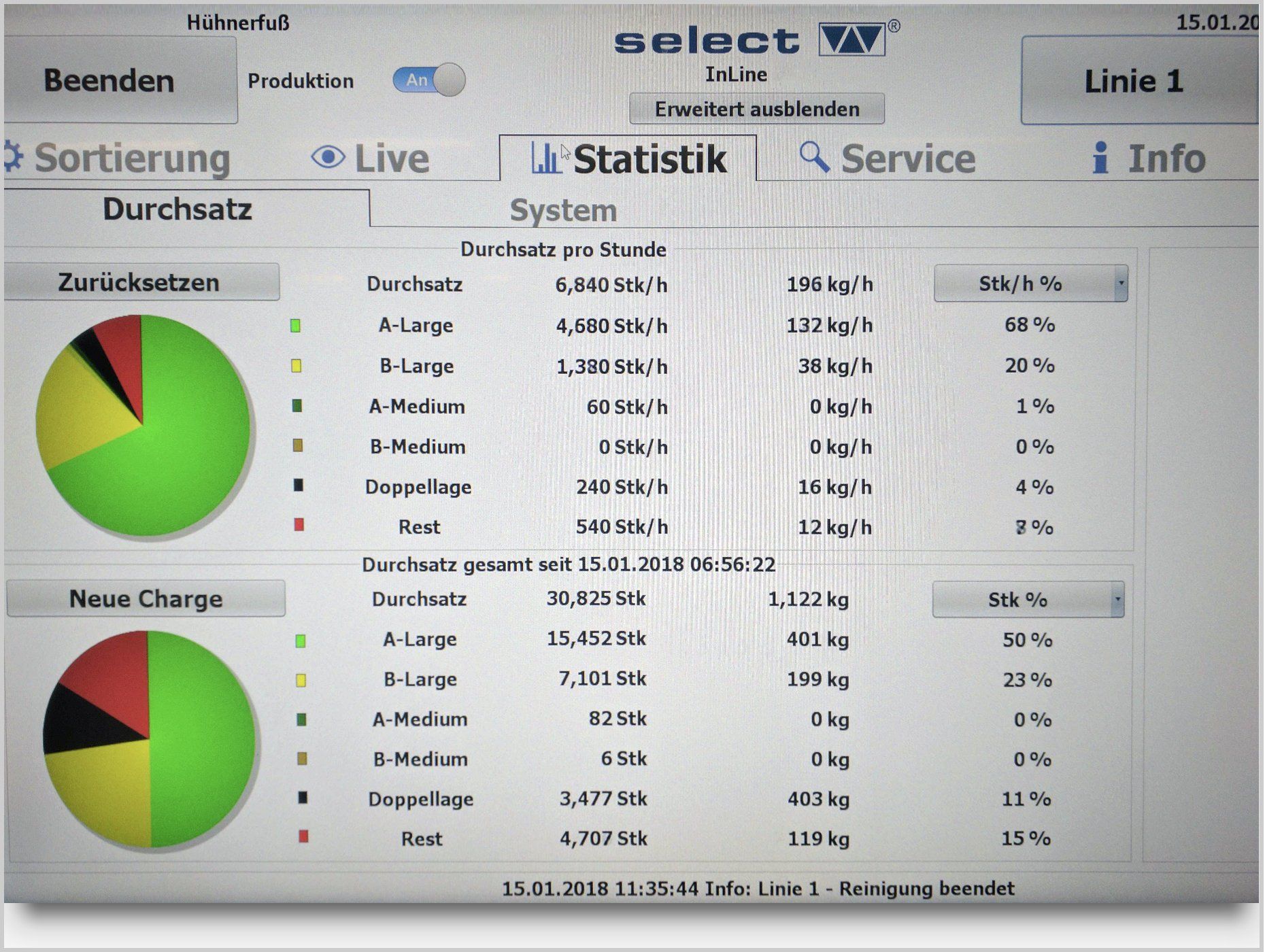

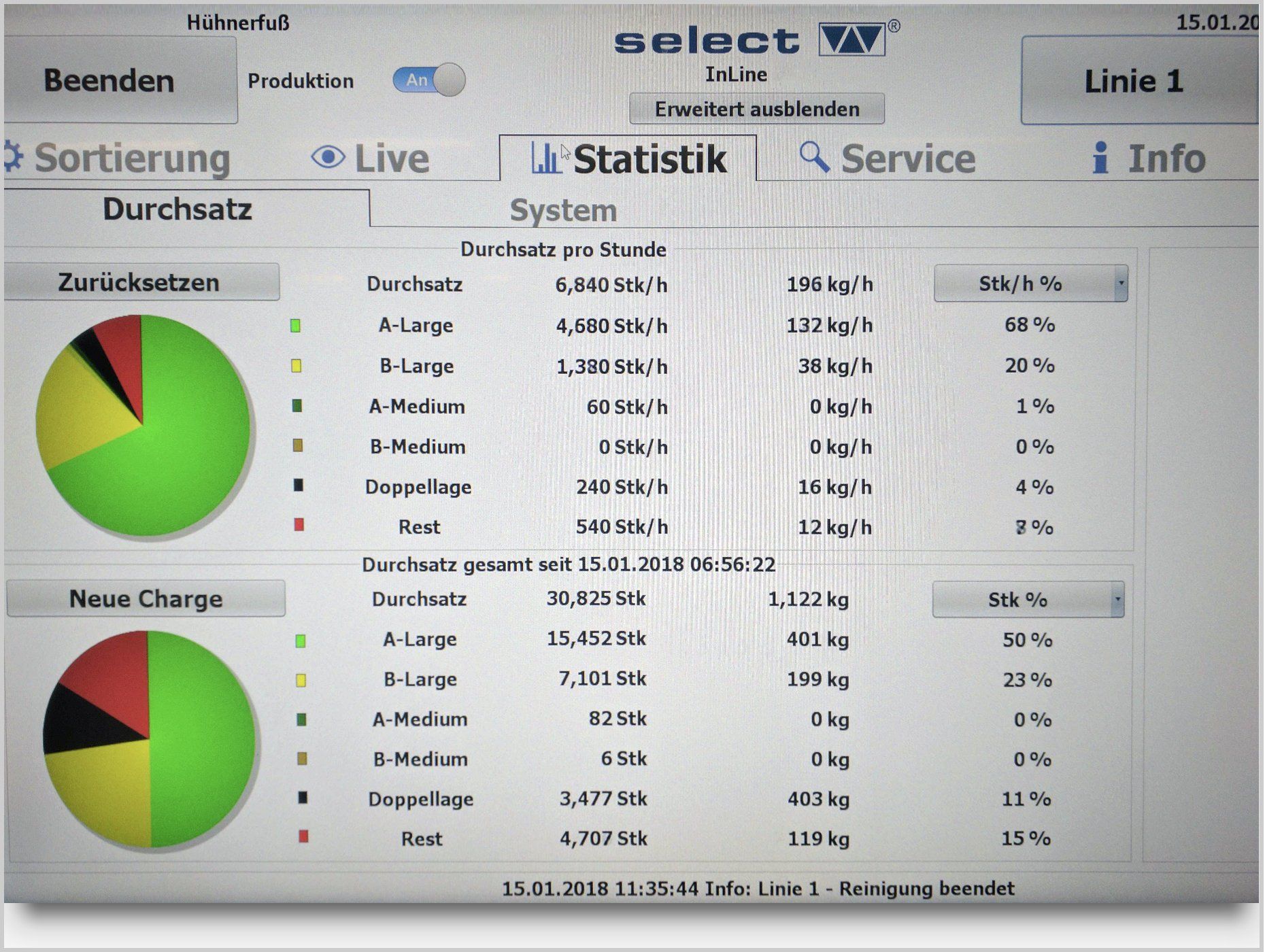

The InLine keen eye is very high-tech but the operator doesn’t need to be. They get simple, clear statistical and operational information from the large colour touch screen which also provides live images of the product and defects allowing quick and easy set up or adjustment.

- You’re not on your own...

Help with set-up, software updates and fault diagnosis are available free of charge via an encrypted internet connection.

- Hassle-free

The simple hygienic design with easy access, coupled with remote service, gives the user many years of fault free service and very low downtime.

- Capacity

- Up to 50 tonnes/hr depending on number of channels and product size or weight

- Up to nine sorting results available

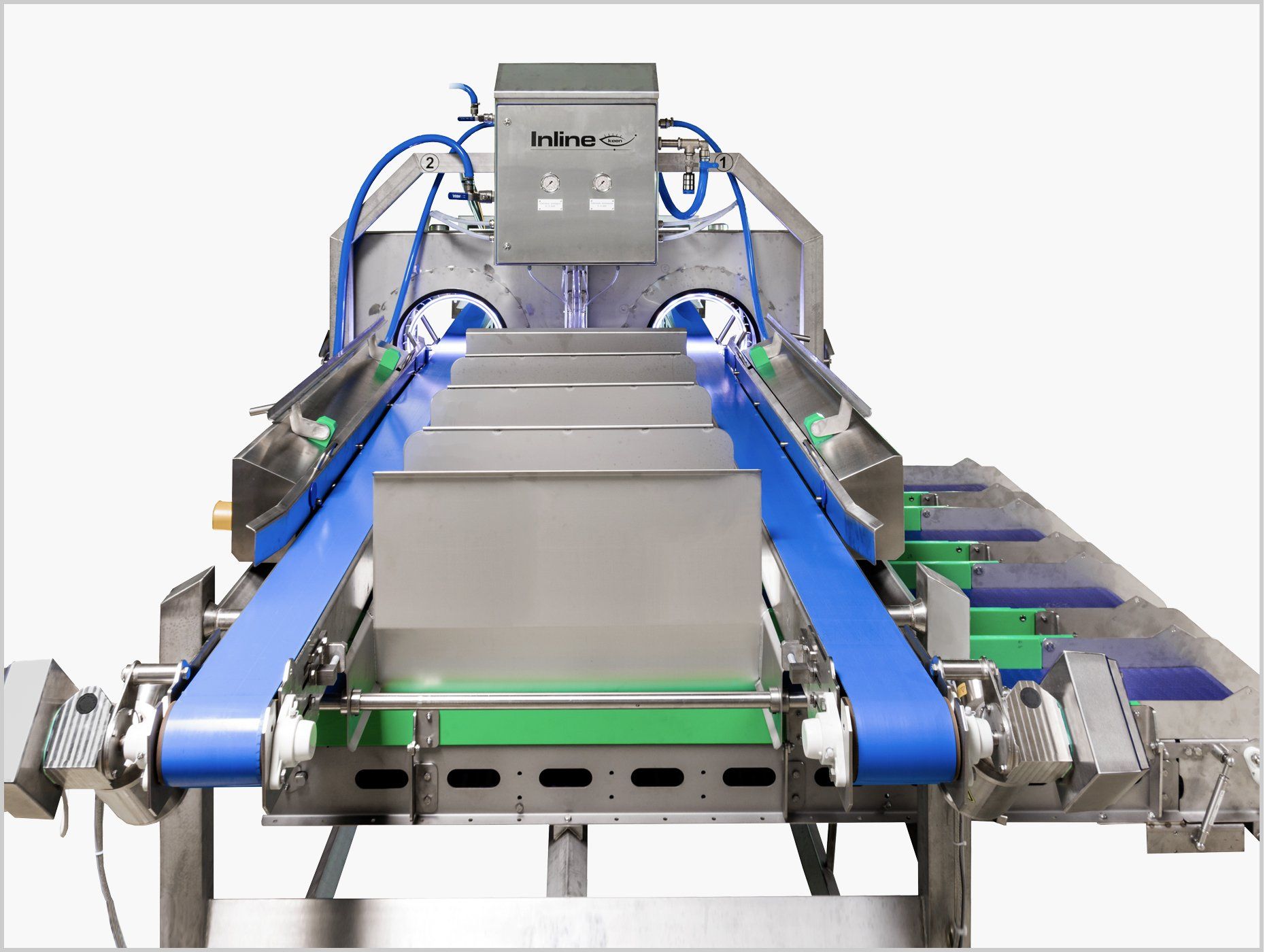

- Vision system

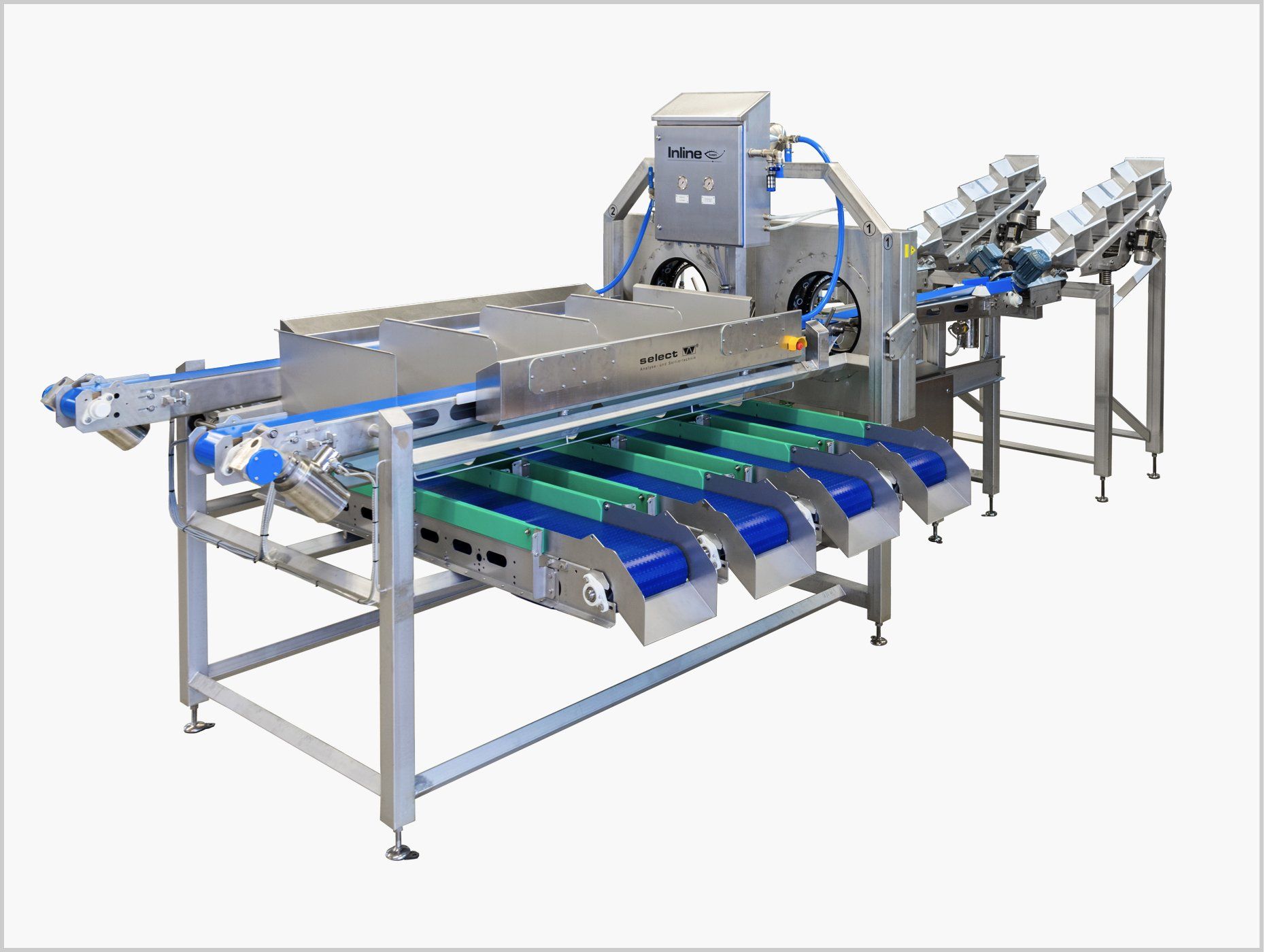

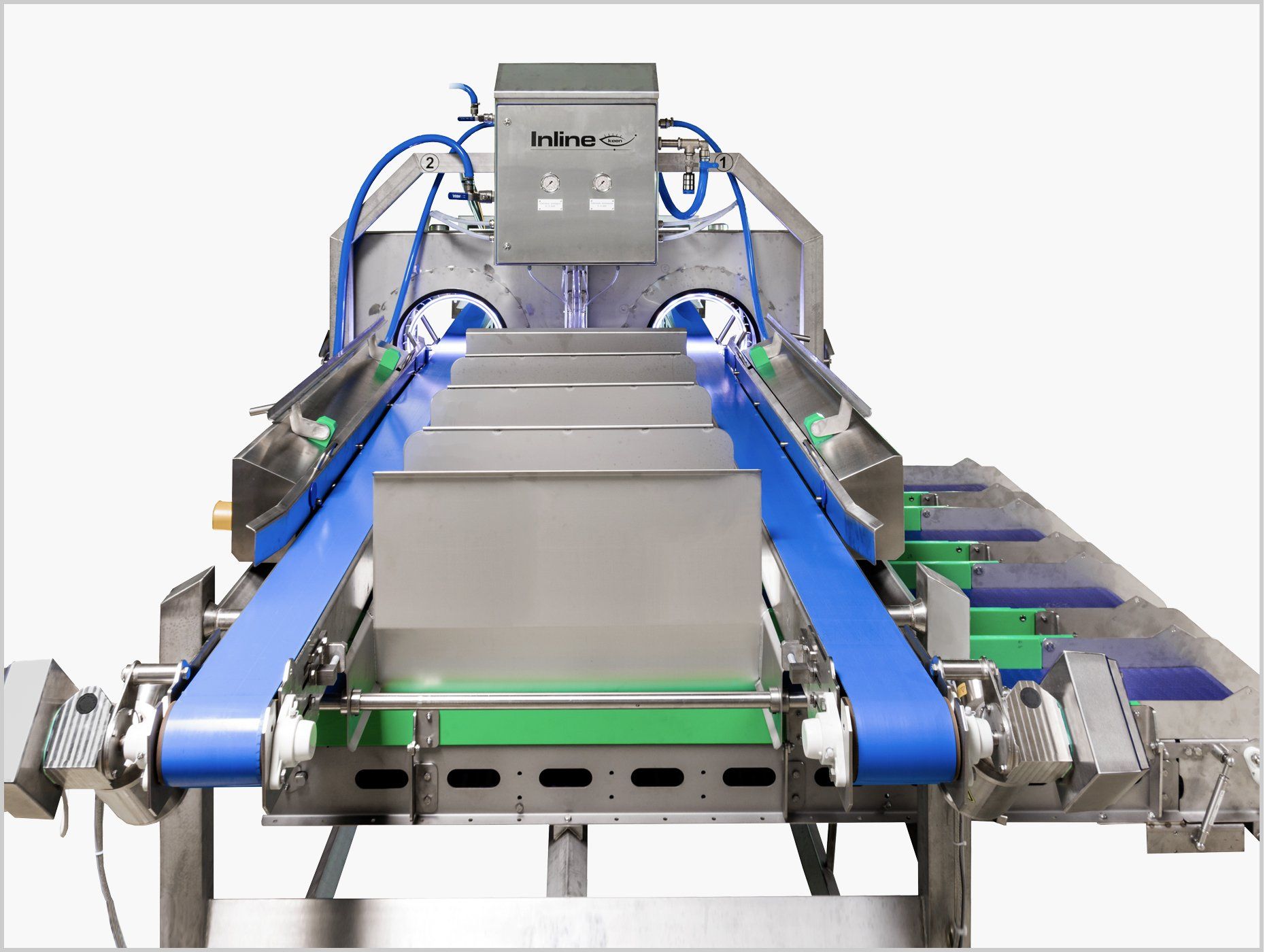

- 360° vision by four high resolution colour cameras

- Entire product surface is scanned

- Durable, power saving LED lighting with many years lifespan

- Automatic cleaning system maintains vision clarity during production

- Ejection system

- Patented finger wheel for large products, or compressed air blast for small products

- Chutes and outfeed conveyors provided at each rejection point

- Simple operator assignment of grading channels

- Grading parameters

- Colour identification of defects.

- Size measurement in all three dimensions

- Weight estimation from volume calculation

- Assessment of product shape or form

- Operator interface

- Full HD 21” colour touch screen

- Easy, clear adjustment of sorting criteria

- Simple menu set-up for different end products

- Detailed statistical information

- Extensive control, fault monitoring

- Remote Service

- Connection by manufacturer via military grade encrypted VPN

- Complete remote control and diagnosis of faults

- Assistance with set-up and analysis of product and defect images

- Software updates and operational improvements without the need for skilled engineering back up

- Hygienic design

- Self cleaning during production combined with simple, safe and easy access for hygiene staff makes the InLine keen eye suitable for the highest grade of food production

Get In Touch

Have a question? Need more information?

Thank you for getting in touch.

We will get back to you as soon as possible

Please try again later

Contact Us

Shareteq Ltd

PO Box 1002, Spalding,

Lincs, PE11 1WE

T +44 (0)1775 710100

Sitemap

Processing

Contact Us

PO Box 1002, Spalding, Lincs, PE11 1WE

T +44 (0)1775 710100

Sitemap

© 2024 Shareteq Ltd

Processing